In today’s competitive market, where efficiency and innovation reign supreme, leveraging can packaging machines can provide a significant edge for companies in various industries, particularly in food and beverage, pharmaceuticals, and household products. These advanced machines not only streamline production processes but also enhance product quality, reliability, and market competitiveness.

Enhancing Efficiency and Speed

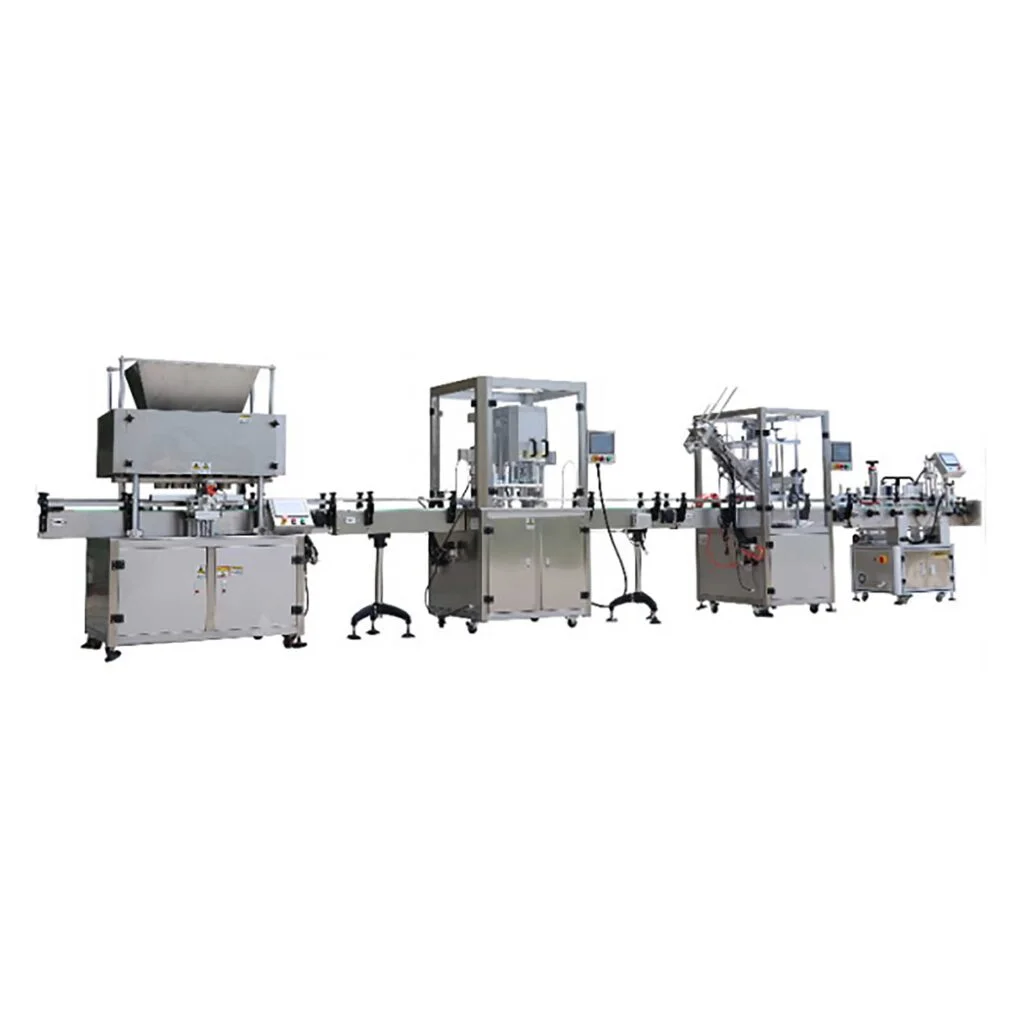

Can packaging machines are designed to automate the packaging process, significantly reducing manual labor and increasing production efficiency. These machines can handle various tasks, including filling, sealing, labeling, and packing, all in a fraction of the time it would take manually. This speed advantage allows companies to meet increasing consumer demands promptly and efficiently. For instance, in the food industry, where freshness and quick delivery are critical, can packaging machines ensure that products are sealed and ready for distribution swiftly. This efficiency not only improves customer satisfaction by reducing lead times but also minimizes operational costs associated with labor and downtime.

Ensuring Product Quality and Consistency

Consistency in product quality is another crucial benefit of can packaging machines. These machines are calibrated to perform precise measurements and operations, ensuring that each can is filled with the exact amount of product specified. This precision minimizes product wastage and maintains uniformity across batches, which is essential for brand reputation and customer loyalty. Moreover, primary packaging material s incorporate advanced technologies such as sensors and automated quality control systems. These systems can detect any deviations in packaging parameters, such as seal integrity or fill levels, ensuring that only products meeting strict quality standards reach consumers.

Flexibility and Customization

Another competitive edge offered by can packaging machines is their versatility and ability to handle various packaging formats and sizes. Whether companies need to package different volumes, shapes, or types of cans, these machines can be adapted and configured accordingly. This flexibility allows businesses to respond swiftly to changing market demands and consumer preferences without the need for extensive retooling or downtime. Furthermore, can packaging machines can accommodate customization options such as labeling, coding, and branding enhancements.

Sustainability and Cost Efficiency

In today’s environmentally conscious marketplace, sustainability is a key differentiator. Can packaging machines contribute to sustainability goals by optimizing material usage and reducing packaging waste. These machines are designed to minimize product loss during filling and sealing processes, thereby reducing the overall environmental footprint of packaging operations. Moreover, the efficiency gains achieved with can packaging machines translate into cost savings over time. By streamlining production processes, reducing labor costs, and minimizing product waste, companies can improve their profitability margins while maintaining competitive pricing in the market.

Leveraging can packaging machines provides a compelling competitive edge in today’s dynamic market landscape. From enhancing production efficiency and ensuring product quality to offering flexibility in packaging formats and contributing to sustainability goals, these machines are indispensable assets for companies striving to stay ahead at www.levapack.com. By investing in advanced can packaging technology, businesses can streamline operations, improve brand reputation, and ultimately, drive growth and profitability in their respective industries.